New Efficiency Classes for Low-Voltage 3-phase Motors

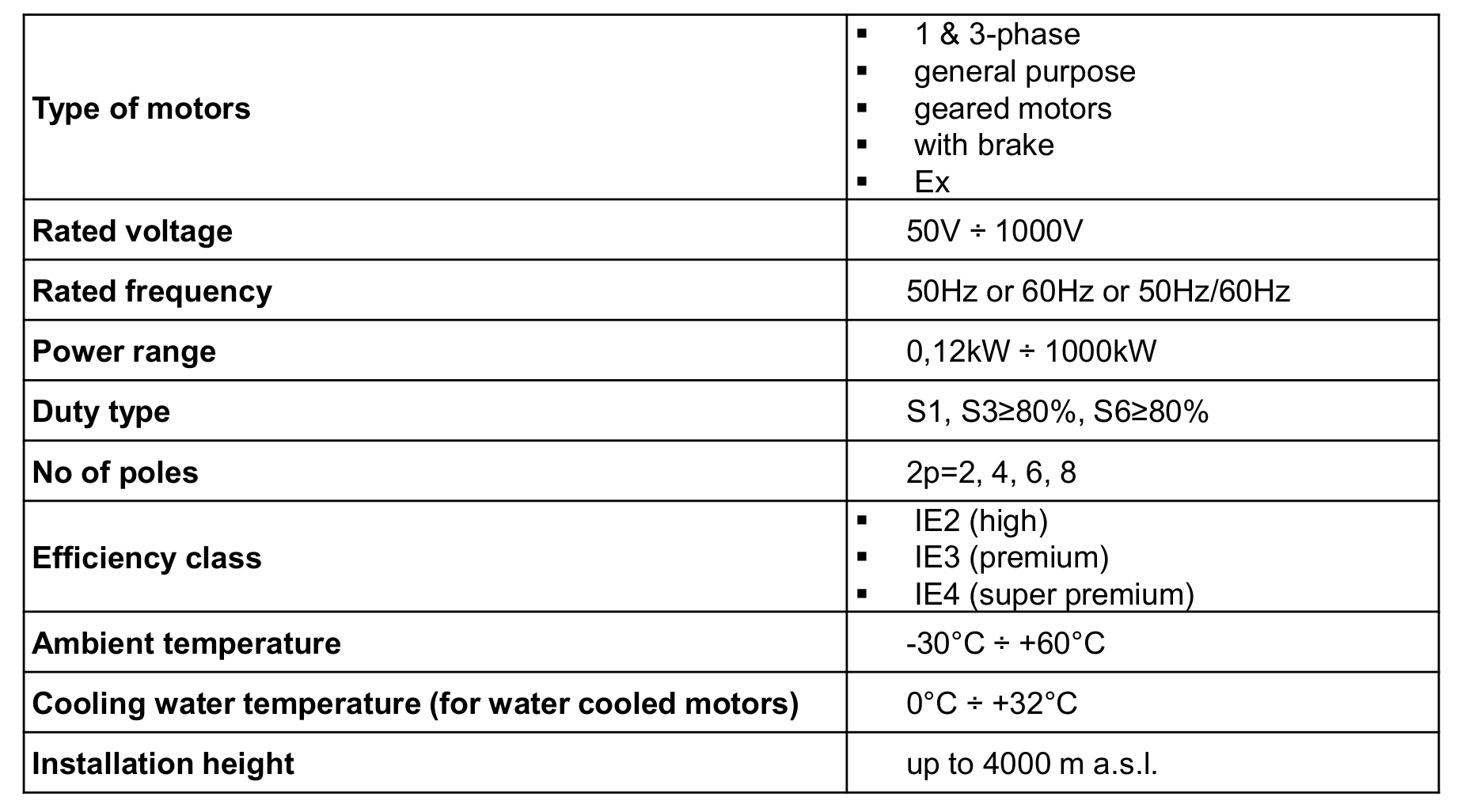

Along with the international discussion on energy efficiency a worldwide harmonized energy efficiency standard classification system has been established for low-voltage three-phase asynchronous motors.

For many years low-voltage three-phase motors have been sold in the European Union in three efficiency classes EFF3, EFF2 and EFF1.

Aside from this, many different efficiency classification systems have been introduced and well-proven in many countries all over the world.

This was the reason for the International Electrotechnical Commission IEC to develop and publish an energy efficiency standard which replaces all the previous national issues. In parallel IEC developed and issued a new standard for determining motor efficiency.